Block Board

Blockboard, also known as lumber-core plywood, is a type of engineered wood product used in various construction and woodworking applications. It is made by sandwiching a core of wooden strips or blocks between two layers of veneer or thin sheets of wood. The blocks are typically made from softwood, like pine or cedar, and are glued together to form a solid core.

Advantages:-

Strength and Stability : Blockboard is known for its structural integrity and resistance to warping or twisting. The solid wood core provides excellent strength.

Smooth Surface : The veneer layers on both sides of the core create a smooth and even surface, making it suitable for finishing with paints, stains, or laminates.

Easy to Work With : Blockboard is relatively easy to cut, shape, and join using common woodworking tools and techniques.

Flush Doors

Plywood doors are interior or exterior doors made primarily from plywood, a type of engineered wood product. Plywood consists of thin layers of wood veneer that are glued together with the grain of adjacent layers oriented at right angles to each other. This construction method gives plywood doors greater strength and dimensional stability compared to solid wood doors. Here are some key points to consider about plywood doors:

Material : Plywood doors are typically constructed using various grades of plywood, which can range from basic, less expensive options to high-quality, hardwood plywood for a more premium look.

Durability : Plywood is known for its strength and resistance to warping and cracking, making it a durable choice for doors. The longevity of the door depends on the quality of the plywood used and the environmental conditions to which it is exposed.

Plywood

Plywood is a type of engineered wood product made from thin layers of wood veneer that are glued together. These layers, or plies, are usually oriented with their grain direction at right angles to the adjacent layers to improve strength and reduce the likelihood of splitting. Plywood is commonly used in construction, furniture making, and various other applications due to its versatility and durability.

Composition: Plywood is typically made from an odd number of plies (usually three or more) that are bonded together using adhesive. The most common adhesive used is phenol-formaldehyde or urea-formaldehyde.

Grain Direction: Plywood sheets are composed of an odd number of layers, and the grain direction of adjacent layers is typically perpendicular. This cross-grain construction enhances the strength and stability of the plywood.

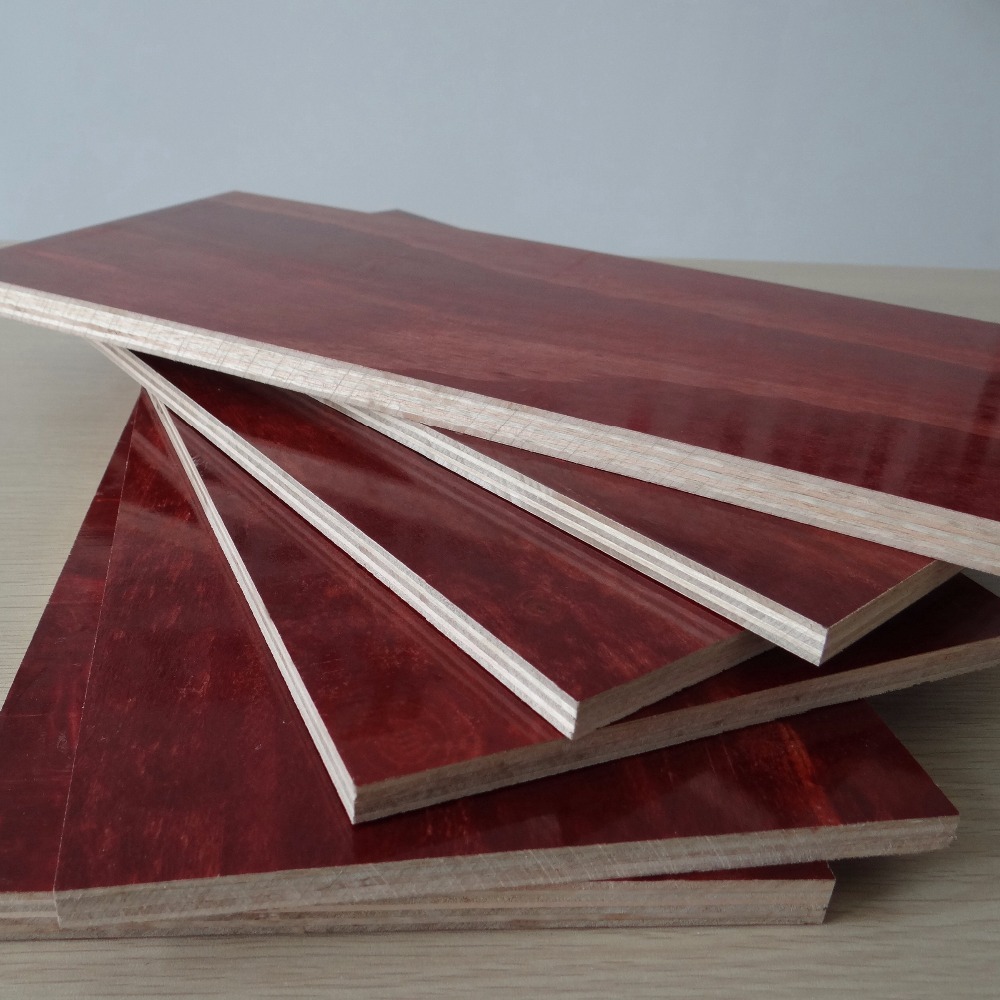

Shuttering Plywood

Shuttering plywood, also known as sheathing plywood or formwork plywood, is a type of plywood specifically designed for use in construction projects, particularly in concrete formwork. It serves as the mold or template into which concrete is poured and allowed to set, taking on the desired shape and structure. Shuttering plywood has several characteristics that make it suitable for this purpose:

Durability: Shuttering plywood is constructed to withstand the pressure and weight of wet concrete without warping or deforming. It is typically made using strong, durable wood veneers and often includes a waterproof coating to protect it from moisture.

Smooth Surface: The surface of shuttering plywood is smooth to ensure that the concrete will have a clean and even finish. This is important for the final appearance of the concrete structure.

Standard Sizes: Shuttering plywood is available in standard sizes and thicknesses to fit various construction requirements. Common thicknesses include 12mm, 15mm, and 18mm, and standard sheet sizes are 4x8 feet or 3x6 feet.